Daniel Wells, a professor and researcher at Auburn University, first began looking at container farming a few years ago.

It started when Alabama Power (a utility company) purchased a container farm from Freight Farms and Wells went to look at it. He also was able to work with one when a restaurant in Montgomery, Alabama bought the container farm from Alabama Power and another model from Freight Farms.

“We had helped them a little bit with some technical stuff,” he says. “So when it was time for us to get our own container farms, which we had wanted to do, Freight Farms was an obvious choice because we had some experience with them.” Currently, Wells says the main crop grown in the farms are spring mix that are served in campus dining salad bars.

The appeal of container farming at Auburn, Wells says, starts with campus dining. His department has a partnership with campus dining to grow food on campus for dining halls. Considering changing weather, consistent demand for 30,000 students and more, container farming made sense.

“We aren't in the quantity business,” Wells says. “I think the students that eat the spring mix that comes from the farms are experiencing the highest quality.”

Additionally, Wells said his department wanted a “manageable” version of vertical farming on campus. To start, they ordered two Freight Farms models. While Wells is ultimately responsible for the farms, he says they are a student-led project. There's a grad student or a research assistant who is in charge and they help students do crop scheduling and figure out what crops to grow. Currently, four students work on the container farms and grow the crops. Harvests and deliveries are then coordinated with the chefs in the various dining halls on campus.

“I've really enjoyed working with the University of Auburn where students are trained on the technology and they are constantly doing experimentation on different techniques to pull out different characteristics in crops or drive yields,” says Rick Vanzura, Freight Farms CEO. “And they collaborate with our different farmers, so they spend time interacting with MGM Greens in Birmingham, Alabama that uses our farms to supply restaurants.”

Having the farms also helps train the next generation of growers, Wells says. They not only get to learn how to grow lettuce in a high-tech environment, but also get to trial crops such as arugula, bok choy, radishes and strawberries in a controlled environment.

“It's really valuable for them and their future careers,” he says. “We already have a success story. My first grad student that was in charge of the whole thing got recruited as a head grower at Soli Organic and took that job. That's what we hope continues to happen.”

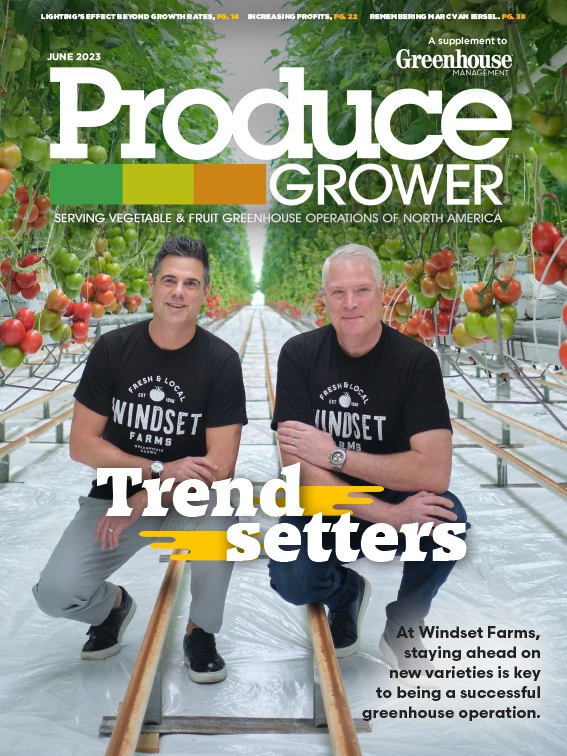

Explore the June 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- TIPA Compostable Packaging acquires paper-based packaging company SEALPAP

- Divert, Inc. and General Produce partner to transform non-donatable food into Renewable Energy, Soil Amendment

- [WATCH] Sustainability through the value chain

- Growing leadership

- In control

- The Growth Industry Episode 8: From NFL guard to expert gardener with Chuck Hutchison

- 2025 in review

- WUR extends Gerben Messelink’s professorship in biological pest control in partnership with Biobest and Interpolis