lot has happened since Produce Grower talked with Ryan Cramer, founder and president of Alberta’s Big Marble Farms, back in 2018 (bit.ly/BigMarbleFarms). Despite a global pandemic, Big Marble has more than doubled its production area and nearly doubled its employee count. The company has also launched a sustainability initiative focused on “The” Big Marble — planet Earth — from which it takes its name.

As Cramer looked ahead in 2018, he advised, “You‘ve got to be always moving forward … You always have to be constantly innovating and adapting to the changes …” Four years later, it’s clear the team at Big Marble Farms has stayed true to those words.

Always growing

Producing vegetables year-round on the Canadian Prairies is just one way Big Marble’s motto “Always Growing” finds life. The company has steadily grown in recent years. A 2020 10-acre greenhouse expansion followed by a 10-acre expansion in 2021 brought the company’s area under glass to 55 acres. A January 2022 acquisition of a local 24-acre facility increased Big Marble’s production footprint to 79 acres.

The company now has nearly 3.1 million square feet in year-round production. Cramer says the 365-day program is a “big deal.” The push for four-season production has strengthened in recent years. “Retail really wants to see everything growing year-round,” he says.

Cramer shares that expansion during a pandemic was a rollercoaster. But all worked out in the end. With materials already ordered, the ball was rolling on 2020 construction when COVID hit. While labor was affected, the impact was minimal and targets were met.

But by the 2021 expansion, the team felt the effects. Supply chain issues led to inflated construction costs and lots of delays. Though projected planting dates moved back a few weeks, plants still went into the greenhouse at a reasonable date.

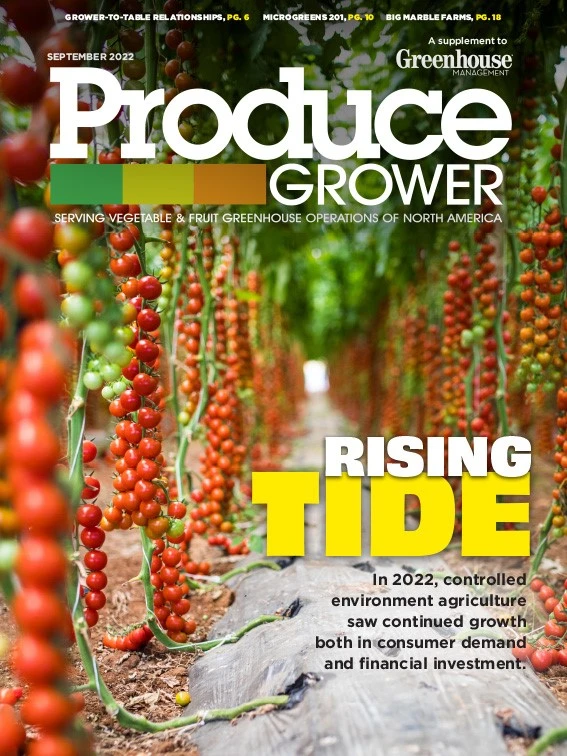

With the physical expansion, Big Marble expanded its crop selection, as well. While mini cucumbers and Long English cucumbers ruled the farm’s high-wire production in 2018, the new areas house tomato production, from on-the-vine to beefsteaks, Romas and snacking varieties.

The lit areas of Big Marble greenhouse production, old and new, remain under high-pressure sodium (HPS) lights. The company has trialed LED (light-emitting diode) interlighting with reduced HPS toplighting in recent years. While results have been positive, Cramer feels the return on investment for an LED switch isn’t where he’d like to see it yet.

Production pinches and partnerships

Like construction, pandemic ups and downs impacted Big Marble production. Cramer cites the panic buying — from toilet paper to cucumbers — that occurred in COVID’s early days.

“The shelves were empty and then so were we,” he recalls. Then suddenly, pantries and shelves were full. Farm sales and purchase orders came to a halt, even though produce didn’t stop.

As supply and demand eventually normalized, the pinch shifted to production costs. “We’re seeing across the board expenses increased in the double digits,” Cramer says, citing price increases up to 20% on natural gas, electricity, cardboard, plastics and more.

And while consumer prices rise, Cramer says farmers don’t see those gains. Growers already dealing with tight margins, especially smaller growers, are struggling with increased expenses as commodity pricing stays the same.

Though not related to today’s rising costs, Cramer says a marketing initiative between Big Marble Farms and the RedHat Co-operative, Ltd. group of growers is one of the company’s most significant developments since 2018.

Since its founding, Big Marble Farms has been a RedHat member, and the Cramer family’s co-op extends even farther. Over the last six years, a progression of RedHat-grown produce began shipping under the Big Marble label. As of 2020, all produce grown by RedHat growers is marketed and sold under the label of Big Marble Farms.

Cramer stresses Big Marble Farms did not buy the co-op, contrary to reports. RedHat still operates with all member-growers, including Big Marble, working together to make decisions. “The produce is simply being marketed under the Big Marble Farms brand,” he explains.

The combined portfolios mean the Big Marble label represents “just shy of 200 acres” of Alberta produce production. Eggplant, peppers and living lettuce augment Big Marble’s tomatoes and cukes.

Community and curtains

Cramer shares that Big Marble Farms has always enjoyed local community support. Though he prefers not to broadcast the company’s community involvement, Big Marble supports its community through many avenues.

One unexpected way the company is giving back involves the addition of blackout curtains on Big Marble greenhouses with supplemental lighting.

Several years ago, Big Marble’s county bylaws started requiring blackout curtains to curtail light pollution in all new greenhouse construction. The 2020 expansion marked the first time Big Marble had to install the curtains.

“What ended up happening is we saw the impact that had on the light emitting. We were so impressed by that, we felt compelled to do something about it,” Cramer says. “ … We know that this has had a tremendous impact on our community. So, we wanted to do good for our community and give back a little bit.”

The company created a two-year plan to install blackout curtains in their existing facilities, even though not required. Last year saw a 20-acre install. Another 15 acres will finish this year. “All of our greenhouses that have lights in them will have blackout curtains starting fall and winter 2022, Cramer says.

Sustainability and packaging

Cramer explains that the view of Earth from space inspired the company’s name. A sustainability initiative called Big Marble First refers to the planet, not the produce company. “Big Marble First stands for really looking at making sure that we put our home — the Earth —in front of every decision that we make,” he says.

Reduced plastic use is one focus, balancing sustainable packaging with protective components to optimize shelf life and reduce food waste. “We know that this is going to be a one-step-at-a-time deal,” Cramer says. “This isn’t going to be an overnight fix.”

He’s most excited about the company’s development of a 100% cardboard packaging line. Starting with a series of boxes for snacking tomatoes dubbed “Simple Marbleous,” it’s set to expand to more Big Marble products. The consumer and retailer response has been overwhelmingly positive.

Cramer acknowledges that sustainable packaging comes with value-added costs. Cardboard boxes are filled and closed by hand; previous plastic packaging was completely automated.

Like rising production costs, sustainable packaging economics matter. But Cramer says, “We believe in this 100%.” He expects retailers and consumers to believe in it, too, and be willing to share in those value-added costs, while Big Marble eats a share.

Extended family and future

Family is a priority at Big Marble Farms. “It’s what drives everything that I do on a daily basis. It’s what gets me up in the morning. My kids and my wife are the people that I want to make the most proud of me,” Cramer says.

His father and uncle, both co-founders, remain part of the team — though they’re more behind the scenes these days. Two cousins are main growers.

But family at Big Marble extends to its 375 employees, up from 190 in 2018. “I can’t say enough about the team that I work with here on a day-to-day basis,” Cramer says. “ … The Big Marble Farms family. Watching that grow and building that team has probably been the most rewarding part of expanding over the years.”

Still moving forward, Cramer stays focused on the local community and surrounding provinces of Alberta, Saskatchewan and Manitoba.

“We consider the Prairie Provinces to be the region that we want to supply,” he says. “We’re really not interested in world global domination. We just want to keep it local. We want to be able to offer the people of The Prairies a local option. That’s our goal.”

Explore the September 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- TIPA Compostable Packaging acquires paper-based packaging company SEALPAP

- Divert, Inc. and General Produce partner to transform non-donatable food into Renewable Energy, Soil Amendment

- [WATCH] Sustainability through the value chain

- Growing leadership

- In control

- The Growth Industry Episode 8: From NFL guard to expert gardener with Chuck Hutchison

- 2025 in review

- WUR extends Gerben Messelink’s professorship in biological pest control in partnership with Biobest and Interpolis