Bluehouse Greenhouse Inc. is currently readying its 2.8 million square-foot greenhouse and energy park. Through this formidable crop-growing network, the company will cultivate and market more than 50 million pounds of sustainable fruits and vegetables annually.

Such ambitious plans call for a powerful strategic partnership. Fitting the bill is Longvine Growing Co. — the recently rebranded Houweling US Holdings — which inked a five-year deal with Bluehouse in August to promote the California grower’s high-wire tomato and cucumber crops.

“We are building an ecosystem for premium produce and crops for the best marketers and strongest markets in each region,” says Bluehouse CEO and founder Ari Kashani. “The Longvine team has a history in wire crops, and ties to the industry here on the West Coast. Our strategy is to allow Longvine to do what they do best — market premium-quality products on the high-wire side.”

Facility nuts and bolts

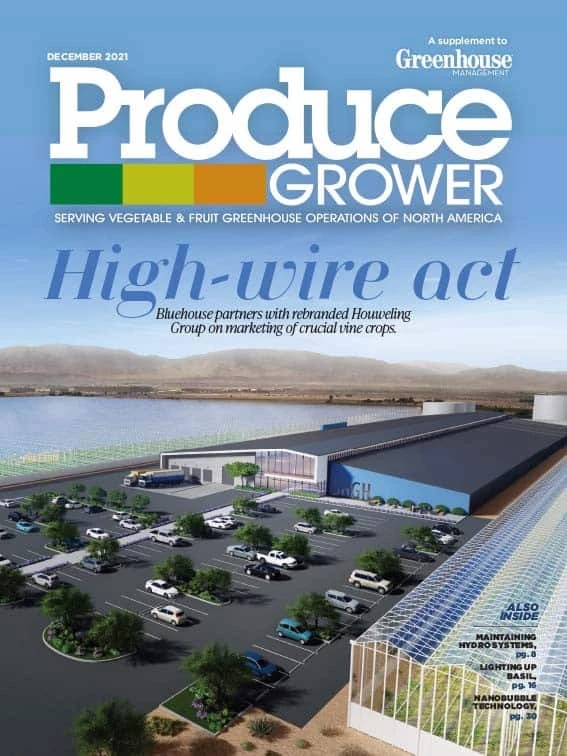

Bluehouse will break ground on its 58-acre flagship facility by year’s end, a project encompassing 38 acres for tomatoes and cucumbers and 20 acres dedicated to lettuce and berry crops. Canadian greenhouse engineer ALPS is orchestrating the design build, with a special focus on renewable processes that meets the mission of both Bluehouse and its new partner.

“We’ve taken sustainability to new heights when designing this facility,” ALPS President Thomas Larssen said in a press release. “From crop balance, energy balance, efficiencies, use of automation, food safety protocols and everything in between, we’ve designed the most secure and resilient operation of this type in the country.”

The forthcoming agro-park facility includes a 13.2 megawatt energy center developed by Chicago-headquartered Endurant Energy. Kashani says the closed-loop, self-sustaining ecosystem — set for production by winter 2022 — will draw from the most advanced elements of sustainable agriculture and energy generation.

“The energy portion of the project is very important for productivity, and Endurant supplies low-cost energy for the most optimal operations outputs possible,” says Kashani. “The goal is to optimize our efficiencies from multiple angles, because energy can be very expensive.”

Collaborating to feed a hungry customer base

The joint venture gives Bluehouse access to a robust customer base alongside a team known for its growing, technical and service know-how. With a focus on local production, Bluehouse seeks to counteract domestic trends where about 60% of vine crops consumed in the U.S. derive from other countries.

Kashani says, “We are located in Los Angeles County, which has a population of 10 million residents, and Southern California has 24 million residents. This is a huge, hyper-dense local market we need to supply food to. Who wouldn’t want tomatoes, berries, cucumbers and herbs that are grown in Los Angeles?”

Meeting increased demand for locally grown traceable fruits and vegetables means hurdling unstable climate conditions and a shrinking labor pool. To that end, Kashani points to Longvine’s quarter-century of supplying customers across North America with a cornucopia of healthy, industry-leading products.

Such expertise is crucial as Bluehouse ramps up its new high-tech farm, notes Kashani. The glass greenhouse will harness natural sunlight, resulting in a projected 3,000% higher yield than a traditional farm. Additionally, the highly-controlled, herbicide-free facility will use 95% less water and 90% less labor in maintaining a comfortable plant climate year-round.

Considering Longvine has built hundreds of greenhouse acres across its agricultural footprint in the U.S., Canada and Mexico, leveraging the company’s talented engineers and designers will ensure full optimization of the new facility. Although Bluehouse has its own team to weigh LED lighting benefits and other details, additional onsite engineers can only have a positive impact.

“Having such an incredible ecosystem entails coordination with a team of sophisticated partners,” Kashani says. “All of this went into design and development to create the most advanced, up-to-date facility possible.”

The collaboration comes at an opportune time for Longvine, which launched its rebranding project in early 2020 as the Houweling family exited its ownership position from U.S. operations. Through an exhaustive reimagining process, Longvine accentuated its core approach as the supplier and marketer of choice to its associates.

Dovetailing with the recent sale and transition of a 125-acre greenhouse in Camarillo, California, to cannabis concern Glass House Brands, the Bluehouse deal lets Longvine integrate its numerous strengths — food safety, pack-line efficiency and growing expertise — within a market eager for its primary crops.

“We have a fairly diversified basket — right now, its tomatoes and cucumbers,” says Mike Reed, chief commercial officer at Mona, Utah-based Longvine. “We have a strong base in the California market, and wanted to maintain that.”

Start of a beautiful friendship

Greenhouse design is a critical facet in Bluehouse’s daily processes, while growing several crops in one facility requires cognizance of various environmental controls and climate zones. Food safety is another important operational element, one necessitating refurbishment of closed-off areas within the greenhouse to avoid cross-contamination.

Which brings Holland back to the ag-tech company’s new affiliation with Longvine, a relationship that will only support Bluehouse’s already successful crop-growing history. Drawing on Longvine’s reputation will be instrumental in meeting the increasingly stringent demands within controlled environment agriculture.

“They’re supplying us with IT advice as well as understanding of greenhouse automation systems,” says Holland. “They’re also bringing experience, which is a key ingredient to make all the pieces come together and work well.”

For their part, Longvine officials are excited to connect with a flagship example of sustainable and high-density agriculture, as well as a passionate entrepreneur carrying a robust vision for a modern growing operation.

Reed says that along with IT savvy, Longvine will provide Bluehouse with counsel on crop setup. Longvine will further strengthen the partnership with packhouse efficiency advice and guidance during an impending capital finance raise.

“We’ve got a strong customer base well-known throughout the west, and programs with some of the strongest retail clubs and club accounts,” Reed says. “We’re focused on high levels of service, which also was of interest to the Bluehouse team.”

Reed also has kind words to share about Kashani’s energy-conservation focus and larger love for the industry.“Ari has a great attitude — he has a passion for growing and sustainable methods, which aligns with our Utah footprint,” says Reed. “There’s great expenditure there in tapping into a nearby power plant and utilizing waste energy for our facility. Bluehouse is committed to the energy side of the business and that aligns with us perfectly.”

Bluehouse’s food and energy ecosystem is scheduled to come online within the next year. In the interim, company leaders are thrilled to have an experienced partner on the journey toward cutting-edge, innovative and advanced controlled farming.

“Longvine has a great brand, a strong team of marketers, and strategic people behind them,” says Kashani. “Our focus is supplying the Longvine team as well as folks in other categories with the best product. We have some of the nation’s most premium produce, and Longvine will market those products through their established distribution channels.”

Explore the December 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- TIPA Compostable Packaging acquires paper-based packaging company SEALPAP

- Divert, Inc. and General Produce partner to transform non-donatable food into Renewable Energy, Soil Amendment

- [WATCH] Sustainability through the value chain

- Growing leadership

- In control

- The Growth Industry Episode 8: From NFL guard to expert gardener with Chuck Hutchison

- 2025 in review

- WUR extends Gerben Messelink’s professorship in biological pest control in partnership with Biobest and Interpolis