Energy for heating and lighting greenhouses is typically the second largest production cost. Traditionally, high intensity discharge (HID) lights are used in lettuce greenhouses to supplement light in cloudy and low light winter days. High pressure sodium (HPS) and ceramic metal halide (CMH) are two types of HIDs. These lights are relatively long lasting and inexpensive upfront, but they are less energy efficient because a large portion of energy is converted into heat, and additional cooling may be needed to offset the extra heat. Another drawback of HID fixtures is that light intensity and light spectrum cannot be adjusted. Light-emitting diodes (LEDs) are seeing increased adoption primarily because they reduce energy costs but also due to the flexibility they offer in intensity and spectrum. For red leaf lettuce, it is well-known that blue-light is necessary for the red coloration (which comes from anthocyanins, an important pigment and antioxidant). Because HPS lights are low in the blue spectrum, red lettuce often lacks deep coloration in winter when natural light (including blue) is low. Light spectrum may be used to adjust pigment and nutritional content of lettuce. However, information is lacking on different supplemental lighting sources in terms of their effects on the nutrient content and yield of lettuce. Supplemental lighting can also impact plant water use which impacts irrigation scheduling and need to dehumidify the growing space. We conducted a greenhouse study that compared traditional lights (HPS and CMH) with two types of LEDs (broad spectrum white and red:blue).

The experiment was conducted in a greenhouse in central New York from December to mid-March. Two lettuce cultivars, ‘Rex’ (a common butterhead type for hydroponics) and ‘Rouxai’ (a red oakleaf variety) were used for this study. Seeds were started in rockwool cubes for a week and then transplanted to mini deep water culture (DWC) hydroponic systems under lighting treatments for four weeks. Air was pumped into the nutrient solution to provide oxygen to the rootzone. Four lighting treatments were set up in the same greenhouse: HPS, CMH, red:blue LED (70% red and 30% blue), and white LED (36% red, 27% blue, and 45% green). All treatments were adjusted to have the same intensity of 150 μmol·m-2·s-1 and each day the number of hours of supplemental light was adjusted by computer control to achieve a daily light integral (DLI) of 17 mol·m-2·d-1 under each treatment. Each lighting treatment was implemented on two randomly located benches in the greenhouse and the experiment was conducted over three crop cycles with lighting treatments randomized before each new cycle. The greenhouse had 77/68° F day/night temperature set points. Seedlings were grown for one week in a common environment and then transplanted and grown for four weeks under the lighting treatments. Water-use was recorded three times weekly. After four weeks of lighting treatment, nine plants from each cultivar per treatment area were destructively harvested and data were collected on plant height, width and fresh weight. Three of the nine plants were frozen and analyzed for pigments and nutrients (chlorophyll, xanthophyll, anthocyanin, and mineral element content). The rest of the samples were used for data collection on leaf surface area and dry weight.

The growth factor

Although plants were supplied with the same light intensity and DLI, their growth was significantly affected by the light spectrum. Plants grown under HPS and CMH had larger size and leaf surface area than those grown under LEDs. The HPS and CMH treatments both resulted in greater fresh weight and dry weight than the LED treatments. For example, plants grown under HPS had 24% and 39% more fresh weight, respectively for ‘Rex’ and ‘Rouxai’, than plants grown under red:blue LED. ‘Rex’ had a fresh weight of 150 g under HPS vs. 120 g under red:blue LED. ‘Rouxai’ had a fresh weight of 100 g under HPS vs. 70 g under red:blue LED. While plants grown under HPS had greater fresh weight than those grown under CMH, the difference in dry weight was not statistically significant. In other words, plants grown under HPS were juicier (i.e., held more water) than plants grown under CMH. The two LED treatments resulted in similar fresh weight and dry weight, although white LED resulted in larger size and leaf surface area than red:blue LED. HPS and CMH fixtures produce some infrared heat that warms plant canopy — we believe that increased plant temperature may be one reason for increased growth under winter greenhouse conditions. This suggests growers that adopt LEDs may need to raise their greenhouse air temperature a couple degrees to have similar development rate of HID-grown plants. The HPS fixtures also contain some far-red radiation which can increase leaf expansion thereby increasing light capture and yield.

The nutrition factor

Despite smaller size and weight, plants grown under red:blue LEDs were more nutritious in that they had higher concentration of xanthophylls (lutein and violaxanthin), and for ‘Rouxai’, higher anthocyanins (red pigmentation) compared with plants grown under HPS. For example, plants grown under red:blue LED had 17-22% more violaxanthin than plants grown under HPS. Lettuce is an important source of mineral nutrients such as iron and zinc, however, there was no difference in mineral nutrient content among all treatments. As for water use, plants grown under LEDs used less total amount of water (25-29% less per plant) than their counterparts grown under HPS and CMH. However, when we calculate water use efficiency (amount of water used per gram of plant fresh weight), plants grown under HPS and CMH had higher water use efficiency. Specifically, ‘Rex’ used 11.9 and 14.3 ml of water per gram fresh weight under HPS vs. red:blue LEDs, respectively. For ‘Rouxai’ plants used 17.9 and 20.4 ml per gram of fresh weight under HPS vs. red:blue LEDs, respectively. Thus, under the LEDs used in this experiment more water is required per harvested fresh mass than HID lights.

Recommendations

HPS, as a traditionally used supplemental light in the greenhouse, brought us nice lettuce in terms of plant size and weight. However, LEDs resulted in higher nutritional content of the plants. This result is important for growers whose target customers are those who cares about nutrients and health. In the future growers may use light spectrum as a way to balance growth and nutrition for health conscious customers. Note that our experiment was conducted during winter conditions when there is relatively low sunlight and may not apply to other seasons with reduced need for supplemental lighting. We recommend growers interested in adopting new lights conduct small scale trials with their own crops under their own growing conditions as many factors beyond lighting such as temperature, fertigation and cultivar can greatly impact crop performance.

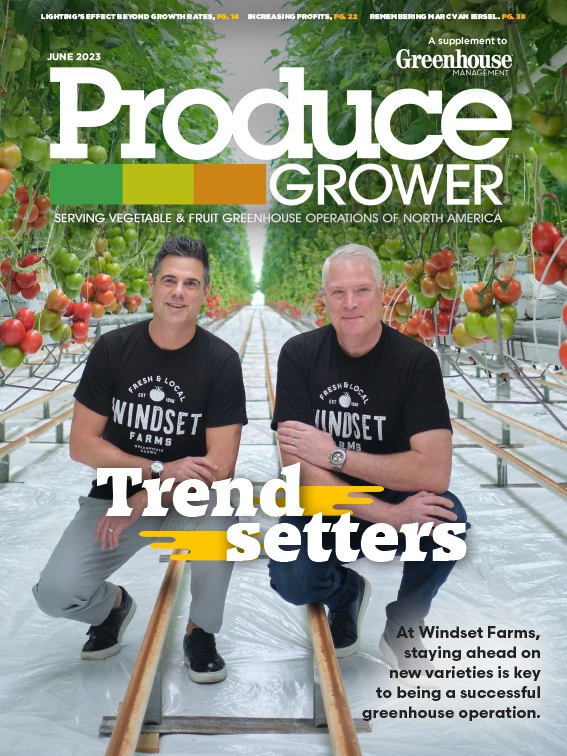

Explore the June 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- University of Evansville launches 'We Grow Aces!' to tackle food insecurity with anu, eko Solutions

- LettUs Grow, KG Systems partner on Advanced Aeroponics technology

- Find out what's in FMI's Power of Produce 2025 report

- The Growth Industry Episode 3: Across the Pond with Neville Stein

- The Growth Industry Episode 2: Emily Showalter on how Willoway Nurseries transformed its business

- How BrightFarms quadrupled capacity in six months

- Oasis Grower Solutions releases two foam AeroSubstrates for hydroponic growers

- FDA Intends to Extend Compliance Date for Food Traceability Rule