Understanding the technical benefits of the fungicides in your disease management program can make or break its efficacy. Here are three important areas to familiarize yourself with to build the most effective fungicide program.

1. Understanding Fungicide Resistance Action Committee (FRAC) Groups is crucial to properly rotating products and implementing a successful management program. When it comes to fungicides, different modes of action (MOAs) help ensure superior, long-lasting control of a broad spectrum of diseases.

“Pathogen resistance to fungicides is well known, and the performance of many fungicides has been affected to some degree by pathogens developing resistance,” says Fulya Baysal-Gurel, research associate professor at Tennessee State University. “So, developing a fungicide rotation program using different modes of action, as indicated by their respective FRAC Groups, is an important action in limiting the risk of fungicide resistance development.”

2. Using novel chemistries like succinate dehydrogenase inhibitor (SDHI) fungicides can give your program a boost. SDHIs have lower loads of active ingredients than other chemistries. They are more active on the binding site of the pathogen, so there are higher levels of activity with less active ingredient, which is a benefit environmentally and in terms of ultimate disease control because it takes less product to do more. The spectrum of disease that SDHI fungicides control is narrow, so the advantage is there are lower use rates and more effective control for specific diseases.

3. Taking preventive action, rather than relying on curative treatments, will provide the best results. Once a pathogen has invaded a crop, the quality is negatively impacted, which can affect sales. In the case of stem rots, once a stem is compromised it can no longer translocate water and nutrients up into the plant canopy, which ultimately results in crop loss.

“Trying to ‘cure’ or eliminate diseases like rusts, downy mildew and powdery mildew once they are established in the plant or crop often requires more applications on a shorter interval than if you are making applications to prevent it,” says Nancy Rechcigl, technical field manager for ornamentals at Syngenta. “This means more expense for the grower.”

Honing in on proper MOA rotation

Using active ingredients with the same MOA repeatedly can result in reduced control and eventually lead to the elimination of certain active ingredients if resistance develops.

“The key to protecting or stewarding the fungicide tools we have available to us is proper use and not overuse,” says Steve Dorer, fungicide brand manager at Syngenta. “By that I mean rotating products to minimize potential resistance development from overuse of any one active ingredient. The key is to make sure that a single active ingredient or FRAC Group (MOA) is not applied to a single crop more than two times in a row without using a different MOA after that second application.”

By varying products within a rotation, growers can get better protection against tough diseases. A well-structured rotation program will consider how to use each products’ strengths and leverage different MOAs at times when they will provide the maximum benefit.

“For a robust rotation, it is important to select three products with different MOA classifications (FRAC Groups) that have proven activity on each disease problem that affects the crop,” says Rechcigl. “Position these products in the rotation based on their strengths and according to their label recommendations. Fungicide labels also include resistance management instructions for you to follow. This may include limiting the number of applications of a product before rotating to a fungicide from another FRAC Group or limiting the number applications per crop.”

Fungicides in FRAC Groups 7 + 11 are excellent choices for broad-spectrum disease control. This type of premix features an SDHI in group 7 and a strobilurin in group 11. SDHI active ingredients have a strong attraction to the binding site within a fungal cell’s mitochondria. When this site is blocked, processes within the mitochondria cease and the fungus is not able to survive, leading to extended protection and long-lasting disease control. A strobilurin fungicide, like azoxystrobin, offers excellent systemic activity and has been shown to move through more areas of the plant to protect existing and new growth.

“Mural fungicide is powered by two active ingredients, SOLATENOL® technology, an advanced generation SDHI, and azoxystrobin, a systemic, broad-spectrum strobilurin fungicide,” says Rechcigl. “Mural penetrates and moves systemically throughout the plant tissue, protecting areas that may have been missed during the application. As a drench, Mural moves into the roots and into the stem and foliage, so all parts of the plant are protected. In addition, Mural has demonstrated plant-health benefits such as increased root density when used at low rates as a spray and as a drench.”

Although 7 + 11 premixes, like Mural, are strong choices for controlling a wide range of foliar and soilborne pathogens, rotating with fungicides in other FRAC Groups can provide enhanced control of more difficult-to-control diseases.

“Combination fungicides in general broaden the spectrum of control and improve overall disease control,” says Dorer. “Both of those actives may control the same disease, but they’re doing it in two different ways. So, that provides an extra level of control.”

The latest innovation from Syngenta, Postiva™ fungicide, in FRAC Groups 3 + 7, is an excellent option to rotate with a 7 + 11 fungicide. Postiva fungicide is powered by ADEPIDYN® technology, the first member of a novel subclass of SDHIs, and difenoconazole, a DMI fungicide. With two modes of action, Postiva provides strong protection and reliable control of difficult diseases such as Fusarium, leaf spots, Botrytis, powdery mildew, as well as bacterial suppression.

“The product was designed to deliver both preventive and curative activity, with long residual performance,” says Rechcigl. “While many fungicides in FRAC Group 3 cause some plant growth regulation, this does not occur with Postiva. While Postiva is a fungicide, it also does an impressive job suppressing bacterial diseases as well, particularly those caused by Pseudomonas spp. and Xanthomonas spp.”

It is important that growers have as many products or “tools” in the toolbox as possible to control the problems they may encounter during production. Once resistance develops, fewer options are available for control, which puts additional strain on the remaining products.

“There is a finite number of pest control resources at their disposal,” says Dorer. “Many of them are grouped into modes of actions. For instance, FRAC Group 7 fungicides are very important and effective, but the problem is if a disease becomes resistant to one of those SDHIs, it could be resistant to all of the SDHIs because the MOA is at the same site. Even though there may be a lot of fungicides on the market, there’s a limited number of modes of action, so if you’re not careful, you can eliminate an entire mode of action from your toolbox for controlling disease. That puts your business at risk because you’re not able to grow crops that are susceptible to the disease that has become resistant. It can also add to your expense because you’ll have to use more product to achieve the same level of disease control.”

What happens if a disease develops resistance?

To maintain the full use of the pest control resources growers have access to, they must adopt best management practices to get the most out of them. If growers use them improperly, they could end up costing their business a lot more in the long term by reducing the kind of crops they can grow and requiring larger amounts of products to control pests.

“The biggest impact disease resistance can have on a grower’s operation is they’ll have to take extra steps to control that disease, including not growing the plant that is the host for that disease, and that will limit their revenue opportunity,” says Dorer. “They may have to also change their growing environment, which may cost extra money. Fungicide resistance does not happen overnight, but once it does it can make disease management more challenging. It truly is an ounce of prevention is worth a pound of cure.”

Visit GreenCastOnline.com/Ornamentals to discover the full fungicide portfolio from Syngenta.

Follow @SyngentaOrnamentals on YouTube to stay up to date on the latest from Syngenta.

All photos are either the property of Syngenta or are used with permission.

Performance assessments are based upon results or analysis of public information, field observations and/or internal Syngenta evaluations. Trials reflect treatment rates and mixing partners commonly recommended in the marketplace.

© 2023 Syngenta. Important: Always read and follow label instructions. Some products may not be registered for sale or use in all states or counties and/or may have state-specific use requirements. Please check with your local extension service to ensure registration and proper use. ADEPIDYN®, GreenCast®, Mural®, Postiva™, SOLATENOL® and the Syngenta logo are trademarks of Syngenta Group Company. All other trademarks are the property of their respective third-party owners.

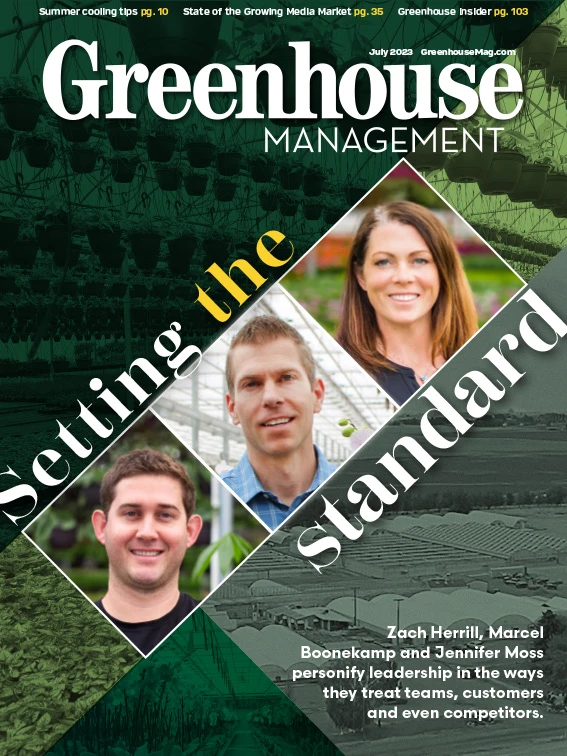

Explore the July 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- John Bonner focuses on purposeful progress as founder of Great Lakes Growers

- The Growth Industry Episode 1: State of the Horticulture Industry

- FDA to Hold Webinar on Updated ‘Healthy’ Claim

- VIDEO: Growing media for strawberries grown under different production systems

- Eden Green Technology CEO Eddy Badrina reflects on challenges, opportunities for CEA

- Why CEA businesses should track carbon KPIs

- UGA professor Erich Schoeller to discuss IPM best practices for CEA at Indoor Ag-Con 2025

- Jason Jurey from Cropking to discuss CEA in K-12 education at Indoor Ag-Con 2025