In March, Windset Farms released the Sonata Pepper to its North American customers. Bred by Rijk Zwaan, a Dutch breeder, the Sonata peppers are an orange Tatayoyo mini pepper variety that, when first debuted at the 2022 Fruit Logistica show in Berlin, won the show’s innovation award.

“It evokes a tropical flavor,” says Windset director of sales Ryan Cherry. “It’s different than anything that’s out there on the market right now.” He adds that it’s a 10 on the Brix scale, indicating a solid nutritional profile.

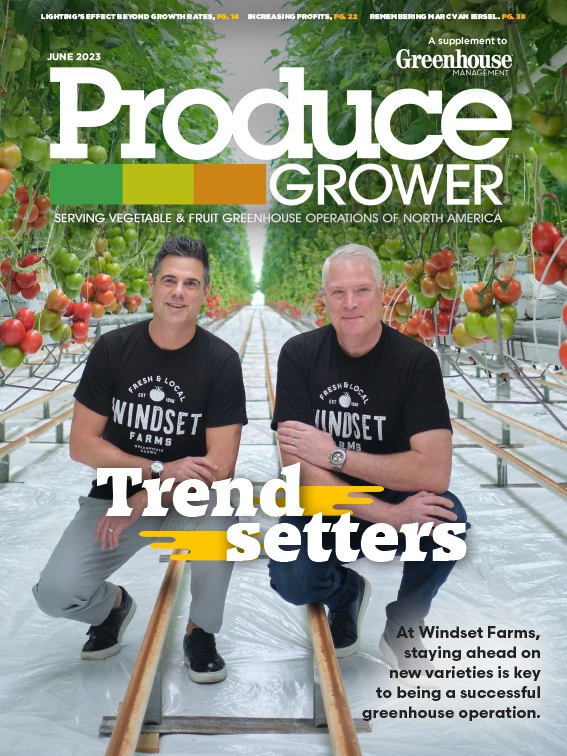

Bringing new varieties to market is at the core of Windset’s business model. The company has two main growing locations — one in its home base of Delta, British Columbia, Canada and another in Santa Maria, California — in addition to growing partners in British Columbia and Mexico. Windset grows cucumbers, tomatoes, peppers and an assortment of specialty items, including lettuces, with the idea to always look for crops that fit what their retail partners are looking for.

“We have to continue to differentiate ourselves from our competition,” Cherry says. “[Offering] new varieties and being the go-to supplier of greenhouse grown produce is huge. You don’t want to respond to the trends, you want to be the trend setter. You want to be first to market, and the retailers want to be first to market, too.”

“That’s always the first question at the trade show,” says Jeff Madu, Windset’s vice president of sales and operations. “They want something that’s a little bit different. Every retailer runs themselves differently too — you have the smaller retailer, the middle ones and the high-end stores.”

Right now, retailers are looking for snacking varieties like the Sonata pepper or mini cucumbers, Cherry explains.

“Retailers have to follow suit because customers are pushing for a lot of snacking varieties, which [has the effect of] broadening out, expanding on greenhouse coverage within a retail shelf,” Cherry says. “So they’ve had to make room for new varieties. And those varieties are there year-round whereas a lot of field varieties — great tasting products, too — could be short crops that are only available over a four- to six-week window.”

“We aren’t solely concentrated on one category, whether that’s peppers or tomatoes or cucumbers,” Madu says. “We cover the entire greenhouse category and we do a very good job of it.”

Trialing, trialing and more trialing

To bring new varieties to market, Windset Farms relies on detailed trialing efforts.

Cherry says bringing a new variety to market can sometimes be a two- or three-year process from first trailing a seed, drilling out the details, figuring out the branding and going through every other step.

With a new variety, like the Sonata pepper or other recent releases such as the YOOM cocktail tomato or the Cameo tomatoes on the vine, the process starts by working with seed partners who can provide them with top quality options. Next, Windset Farms conducts several different trials — and at different scales — for the company to have a clear picture of what a given product offers. That can include trialing at the California greenhouse, trailing at the main facility in British Columbia, trailing in different seasons and finding out what retail partners think of the products.

“Those things are always a bit of wait and see,” Madu says. “It can check all of the boxes, but you have to put it out into retail and be promoted and do well. We also have to get through 12 months to find out what it actually yields. You can have data from a trial house from the seed company, but once you put it into a commercial trial, it’s about how many kilos per square meter that particular item produces. And then we can price it properly. To start it’s a little bit of a guess, but then you get better at growing it and then you can figure out where to price an item like that.”

A lower yield, Madu says, would mean a higher price point for the crop to make sense financially. But at that point, Windset and its retail partners have to ask if customers will buy the crop if the cost is too high.

There’s also the growing side. According to Robert Antscherl, Windset Farms’ head pepper grower, he and the other growers take a number of factors into consideration. For instance: How much labor does a crop require to be grown successfully? Does it require certain nutrition? What kind of growing media does it work best in? And how does it fit into Windset’s climate?

“It’s a lot of data we collect over time until it’s refined,” he says. “And then it becomes easier, like anything.”

Expansion mode

Windset has expended exponentially since its inception back in 1996. What started off as a small four-acre bell pepper greenhouse has grown to over 1,500 acres of growing space across North America. Windset, according to Madu, has strong growing partners in Mexico and British Columbia that are key to their operation, and they are always working to further expand their footprint.

Without detailing specific plans, Madu says the main reason for expansion is to increase the company’s capacity for year-round production. In the company’s current growing facility in Delta, Briish Columbus they rely on natural sunlight coming through greenhouse glass and onto the crops. When the seasons change, and the Canadian winter is cold and dark, that isn’t an option.

“We have a lot of great partners that allow us to supply our customers with greenhouse grown produce year-round,” Madu says, “and our Santa Maria facility also receives plenty of sunlight, so we harvest California grown tomatoes, peppers and cucumbers 365 days of the year.”

“We’re going to really enhance our year-round products,” Cherry says. “It’s going to be exciting. Consumers are asking for year-round greenhouse grown, local produce and we’re going to give it to them.”

Another reason Windset is expanding its offerings, Cherry says, is because of increased awareness of greenhouse-grown products.

“The number of products that are greenhouse grown has definitely grown,” he says. “If we look back to the beginning of COVID, there was a big increase in consumer demand that came on as a result of that and the cut off of food service. We had customers looking for products that we hadn't supplied them or products we thought didn’t fit. But they were just looking for product.”

He says since then, longer term grower-retail partnerships have increased.

“Our whole goal is to provide our customers the best quality 365 days a year,” Madu says. “Consistency is king.”

Explore the June 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- University of Evansville launches 'We Grow Aces!' to tackle food insecurity with anu, eko Solutions

- LettUs Grow, KG Systems partner on Advanced Aeroponics technology

- Find out what's in FMI's Power of Produce 2025 report

- The Growth Industry Episode 3: Across the Pond with Neville Stein

- The Growth Industry Episode 2: Emily Showalter on how Willoway Nurseries transformed its business

- How BrightFarms quadrupled capacity in six months

- Oasis Grower Solutions releases two foam AeroSubstrates for hydroponic growers

- FDA Intends to Extend Compliance Date for Food Traceability Rule